Die Schwerpunkte unserer Forschungsarbeiten resultieren aus der zunehmenden Nutzung des unterirdischen Raums zur geothermischen Energiegewinnung/ -speicherung, zur geologischen Gasspeicherung (CO2, H2). Dies erfordert nicht nur die Bestimmung petrophysikalischer Zielparameter sondern bedarf einer spezifischen Abschätzung der Auswirkung von anthropogen-induzierten Fluid-Gesteinswechselwirkungen auf die langfristige Entwicklung der hydraulischen und mechanischen Eigenschaften geologischer Reservoire. Dazu führen wir Experimente unter kontrollierten Druck- und Temperaturbedingungen durch, die den in situ Bedingungen während der Reservoirnutzung entsprechen. Hierfür stehen uns verschiedene temperierbaren Druckbehälter (s.u.), ausgestattet mit entsprechender Meßsensorik, zur Verfügung, die in enger Zusammenarbeit mit der GFZ-Hochdruckwerkstatt größtenteils selbst entwickelt wurden.Die Versuchsanlagen decken verschiedene Druck- und Temperaturbereiche von 10 MPa - 140 MPa ab, wobei wir Lagerstättentemperaturen von -20 °C bis 550 °C simulieren können.

Multiple Sample Production and Injection Simulator (MuSPIS)

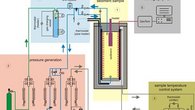

Experimental task:

Controlled long-term investigations on the permeability evolution of sedimentary rocks at simulated pressure- and temperature conditions pertinent to geothermal reservoirs.

Experimental set-up:

The investigations are performed in a set of two apparatuses that allow a variety of continuous petrophysical measurements at a maximum temperature, lithostatic- and pore pressure of 200 °C, 140 and 50 MPa, respectively. The typical flow rate is 15 ml/h and the anticipated run duration will be at least four weeks.

By measuring the permeability of the rock as well as the electric conductivity and pH of the pore fluid one obtains an information about the dynamics of fluid-rock interactions. In addition, so induced changes in ultra-sonic p- and s-wave velocities and the specific electric resistance are continuously monitored during an experiment.

The whole fluid system including the fluid reservoir can be heated and pressurized. Stabilized fluids containing dissolved gases can thus be used and investigated as well.

Finally, by fluid production from one rock sample and injection into a second one, a geothermal reservoir fluid cycle can be simulated at the laboratory scale.

Experimental simulation of reservoir processes

LARS (LArge Reservoir Simulator)

LARS is large volume experimental apparatus for the investigation of anthropogenic induces and natural occurring reservoir processes under simulated in situ conditions in the lab. The sediment sample has a diameter of 0.45m and a length of 1.35m. This large sample allows the installation of „model wells“ for the injection and production of pore fluids as well as the installation of different sensors to monitor various physical parameters during an experiment

The apparatus was set up together with section 4.2 with in the first funding phase of the SUGAR project. This project aims to study innovative methods for the production of methane from methane hydrate.

A prerequisite for these tests was the production of sufficient amounts of methane hydrate in the pore space of the sediment sample from methane dissolved in water. This hydrate formation mechanism is assumed to be responsible for the observed high hydrate accumulations in sandy reservoirs.

For the process monitoring of hydrate formation and hydrate decomposition during production an electrical resistivity tomography (ERT) with 375 electrodes was installed within the second funding phase of the SUGAR project. The ERT allows to distinguish between the conducting pore water and the electrically insulating methane hydrate/methane gas in the pore space.

The system allows to study hydrate formation processes as well as different hydrate production methods in a systematical way.

System for Experimental Petrophysics - SEPP

Measuring the physical properties of rocks under simulated “in situ” conditions in the laboratory is crucial for a comprehensive characterization of natural geological reservoirs. The long-term flow-through apparatus SEPP consists of a total of 6 temperature-controlled oil pressure chambers, whose internal set-up allows combined measurements of permeability, P and S wave velocity, and complex electrical conductivity (leakage current-free 4-pole measurements) on rock cylinders (d = 25/30 mm, lmax = 60 mm). In case a hydrophilic porous membrane is placed between sample and lower measuring head, the device can also be used to determine capillary pressure curves both at drainage and imbibition. Sample holders/ measuring heads made from Hastelloy C276 allow for the use of highly corrosive pore fluids, such as brines and weak acids. In addition, a hydraulic punch is integrated into the lower plug of the pressure vessel, allowing for the application of bi-axial stress conditions.

The pressure vessels are designed for a maximum confining pressure of 60 MPa at a working temperature of 150 °C and thus allow experiments under simulated conditions of underground storage in 1000 - 3000 m depth. Generally, test conditions in a temperature range of -20 to 200 °C can be applied at a correspondingly lower confining pressure. For temperature control, the pressure vessels are equipped either with cooling jackets or oil-filled heating jackets. The pore fluid system for long-term flow tests is dimensioned for a maximum pore pressure of 40 MPa. To perform capillary pressure experiments, the injection system can be replaced by a displacement spindle pump (pmax = 30 MPa, Tmax = 150 °C).

FLECAS-HT

Experimental set-up:

FLECAS-HT is a unique flow-through system enabling the simultaneous measurement of permeability and electrical resistivity (co-axial 4-electrode arrangement) on rock cylinders with a diameter of 30 mm and a length of 75 mm at temperatures of up to 500 ° C. Currently, FLECAS-HT can be operated at a maximum confining Ar-gas pressure of 40 MPa, and a pore fluid pressure of 25 MPa. Due to the corrosive nature of high enthalpy aqueous fluids, the sample must be encapsulated with a gold tube.

Scientific topics:

- Long-term flow-through experiments (weeks to months) at simulated reservoir conditions

- Effect of chemical fluid-rock interactions on hydraulic and electrical rock properties

- Effect of phase transitions (liquid solid/ liquid gas) on physical rock properties

High-Temperature Fluid Measuring Cell

The High-Temperature Fluid Measuring Cell is a flow-through device that allows to measure the electrical conductivity of highly corrosive aqueous fluids in dependence of pressure and temperature. So far, the facility was used to study geothermal high-temperature reservoirs at temperatures up to 425°C and fluid pressures up to 350 bar. Beyond the determination of intrinsic fluid properties, the measuring cell is capable to study the effect of fluid–rock interactions at supercritical conditions. As most steels are not corrosion-resist under long-term exposition of supercritical water, the reactor tube was lined with a pipe of corundum ceramic into which two pairs of current and potential electrodes (Pt) as well as a thermocouple (Pt/PtRh) are sealed. The electrode spacing is variable between 25 and 130 mm, what allows the additional integration of solid material into the measuring cell for reactive flow experiments. Fluid samples can be taken down-stream for chemical analysis.

Permeameter

One of the most important reservoir parameters is the permeability, which defines the ability of a fluid to flow through a porous medium. Different set-ups are available in our labs to determine permeability at different pT conditions. Standard sample sizes (D/L) are 25 mm/50 mm and 30 mm/40 mm, respectively. Permeability is generally measured by steady-state flow (Darcy and Darcy-Klinkenberg, respectively) but the pore pressure pulse method may be applied as well, extending the measurable range towards lower permeabilities yielding 10-18 to 10-12 m2 (1 µD to 1 D).

For routine measurements of permeability, the gas-water permeameter PEPE can be used. Flow can be realized either with gas (argon) or with deionized water. When using gas, the flow-rate is determined with flow-meters permitting a range of 1 to 10,000 ml/min. For flow with water, additional pumps can be attached to the device, monitoring both flow-rate and pressure internally. Confining pressure is generated by gas and is limited to 10 MPa.

For measurements with water at elevated temperatures up to ca. 150 °C a second permeameter is available (BECKI). Here, the maximum confining pressure (gas) is 20 MPa. Again, water flow is realized by pumps internally monitoring pore pressure and flow-rate.

To investigate the long-term evolution of permeability under simulated in-situ conditions we operate additional complex flow-through devices (MUSPIS 1-4, SEPP/SEPP-Hydrate, FLECAS-HT, MTS).

![[Translate to English:] Hochtemperatur-Permeameter](/fileadmin/_processed_/f/9/csm_BECKI_1_3772a8be01.jpeg)

![[Translate to English:] Gas/Wasser-Permeameter](/fileadmin/_processed_/e/2/csm_PEPE_1_d5c442480e.jpeg)

![[Translate to English:] Gas/Wasser-Permeameter](/fileadmin/_processed_/c/6/csm_PEPE_2_bf65156c8f.jpeg)

![[Translate to English:] Gas/Wasser-Permeameter](/fileadmin/_processed_/9/b/csm_PEPE_3_db80617991.jpeg)